Make Every Dose Better

Download Our Free Guide to Discover:

✅ How to cut manufacturing costs with a 2-material supply chain

✅ How to test your drug in BFS containers RISK-FREE (no upfront investment)

✅ How to scale to 15M+ prefilled units per month with BFS automation

Why 72% of Injectable Drugs Fail in Emerging Markets:

- Glass vials shatter, cost too much, and require scarce specialists

- Complex supply chains drown margins with delays and waste

- Regulatory nightmares stall launches for years

What if you could bypass these barriers with a single prefilled device?

The ApiJect Platform: BFS + Pen Needle Tech = Unbeatable Global Delivery

1) Glass Vial Costs, Prefilled Margins

Produce devices cheaper than syringes – while slashing energy use by 55% and water by 100x.

2) 1 Line = 10M Doses/Month

Rommelag® BFS machines run 24/7 – resilient 2-material chain (resin + cannula) included.

3) Test Your Drug RISK-FREE

Get free BFS vials to hand-fill your formula – zero commitment, 48-hour turnaround.

4) Dominate Regulatory Hurdles

Pre-engineered compliance for FDA/WHO – cut approval timelines by 60%.

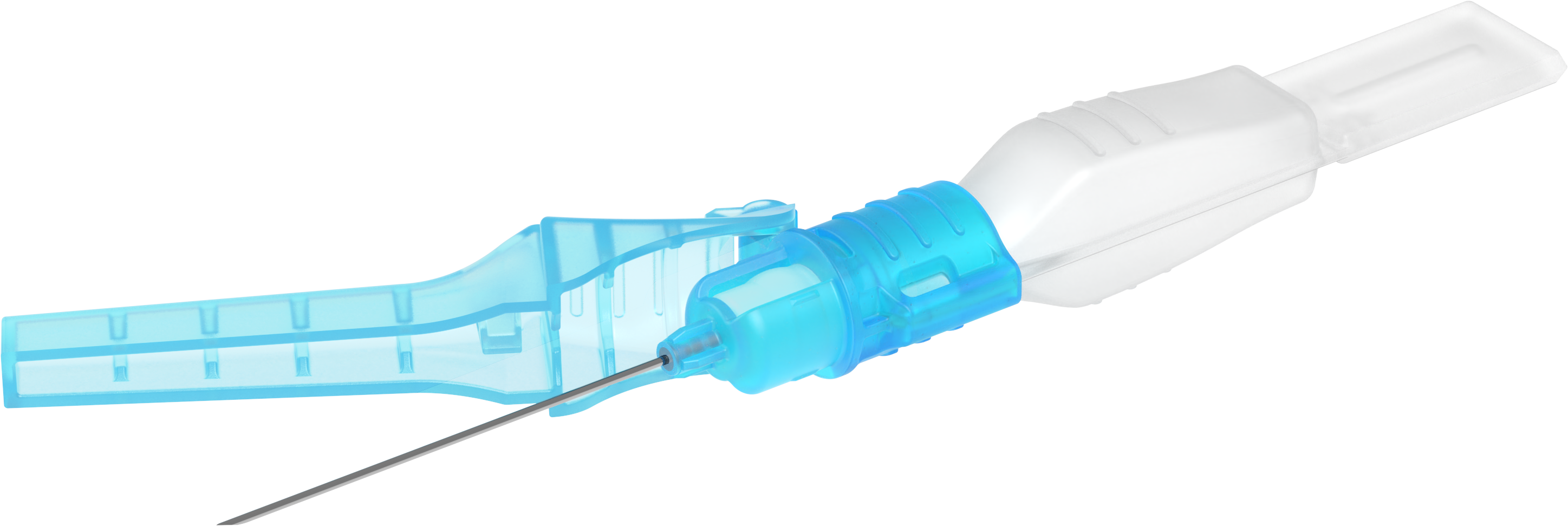

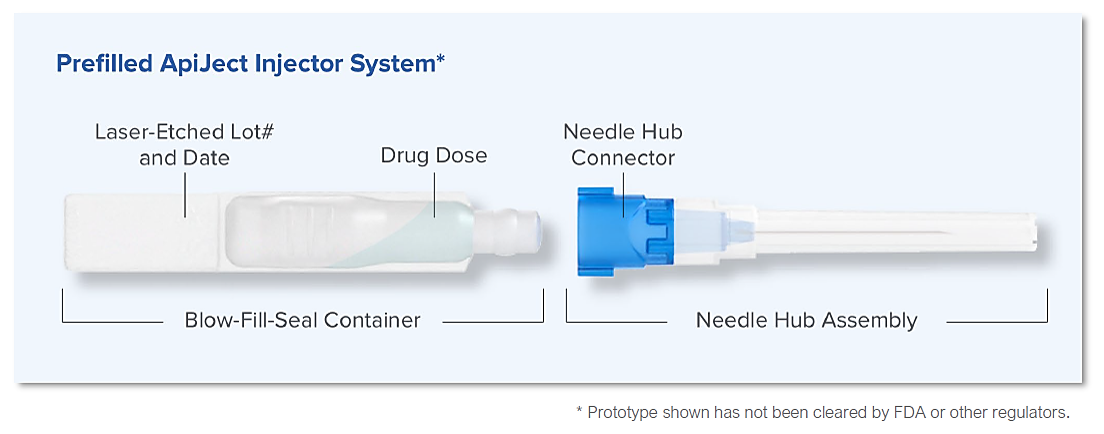

Combining Two Pharma-Trusted Technologies

Blow-Fill-Seal (BFS) fills and finishes billions of doses of pharmaceutical liquids annually because of its ability to scale quickly and economically. ApiJect reliably combines BFS with a pen needle-style hub to transform a BFS container into a prefilled injection device.